Color - TCS34725¶

RGB Color Sensor with IR filter and White LED

Plugin details¶

Type: Color

Name: TCS34725

Status: COLLECTION

GitHub: P050_TCS34725.ino

Maintainer: TD-er, tonhuisman (code), heinemannj (docs)

Used libraries: https://github.com/adafruit/Adafruit_TCS34725 (local copy)

TCS34725¶

Introduction¶

The TCS34725 has RGB and Clear light sensing elements. An IR blocking filter, integrated on-chip and localized to the color sensing photodiodes, minimizes the IR spectral component of the incoming light and allows accurately color measurements.

Specifications:

RGB color and light sensor with 4 channel light sensing readings (Red, Green, Blue, Clear)

Calculated light lux

Calculated color temperature

Adjustable integration time and gain

Neutral 4150 °K temperature onboard LED to illuminate what you’re trying to sense

I2C 7-bit address (0x29) - fixed

I2C pins can be used at 3.3V or 5V

Wiring¶

ESP TCS34725

GPIO-4 (D2) <--> SDA

GPIO-5 (D1) <--> SCL

Power

3.3V <--> 3.3V

GND <--> GND

The onboard LED can be turn off by pulling the sensor LED pin to LOW:

To turn off permanently: Wire the sensor LED pin directly to the microcontroller ground

ESP TCS34725

GND <--> LED

To control via an ESPEasy switch: Wire the sensor LED pin to a spare microcontroller digital pin

ESP TCS34725

GPIO-12 (D6) <--> LED

To control with setInterrupt(): Wire the sensor LED pin to the sensor INT pin

TCS34725 TCS34725

INT <--> LED

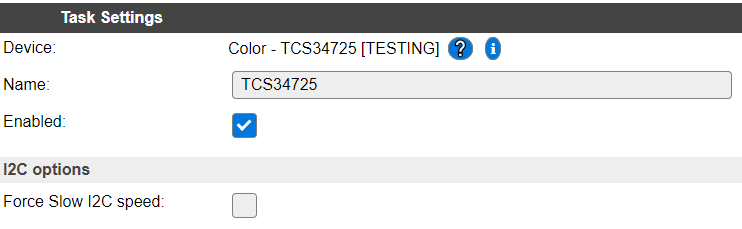

Setup¶

Note

I2C address: 0x29 Can not be changed

Gain and Integration Time¶

The Integration Time of the sensor must be a value between 2.4-700 (in milliseconds)

The gain of the sensor must be a value of 1, 4, 16, 60

In general:

Use the minimum Gain as possible, since increasing the Gain amplifies the noise as well as the signal

Choose an Integeration Time long enough to produce a near full-scale value, since this will give you the most effective use of the sensor’s resolution

To adjust Gain and Integration Time settings:

Switch to Raw RGB data plus the Clear channel

Set Gain to 1

Increase Integration Time until the Clear Channel value reach 65535 (maximum value) => Sensor is saturated

Decrease Integration Time by one level => All channels MUST < 65535

Control that Color Temperature (DN40) value of daylight is not 0

After applying transformation/calibration factors do NOT change your settings of Gain and Integration Time (see chapter “Conditions”)!

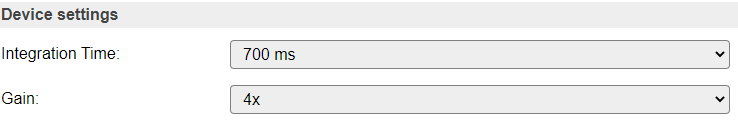

Output settings¶

Raw RGB (0..65535)

Raw RGB (0..65535) transformed (3x3 matrix, below)

Normalized RGB (0-255)

Normalized RGB (0-255) transformed (3x3 matrix, below)

Normalized RGB (0.0000..1.0000)

Normalized RGB (0.0000..1.0000) transformed (3x3 matrix, below)

Color Temperature (DN25 - deprecated) [K]

Color Temperature (DN40) [K]

Ambient Light [Lux]

Clear Channel

For detailed explanations see below chapter “Indicators (recommended settings)”.

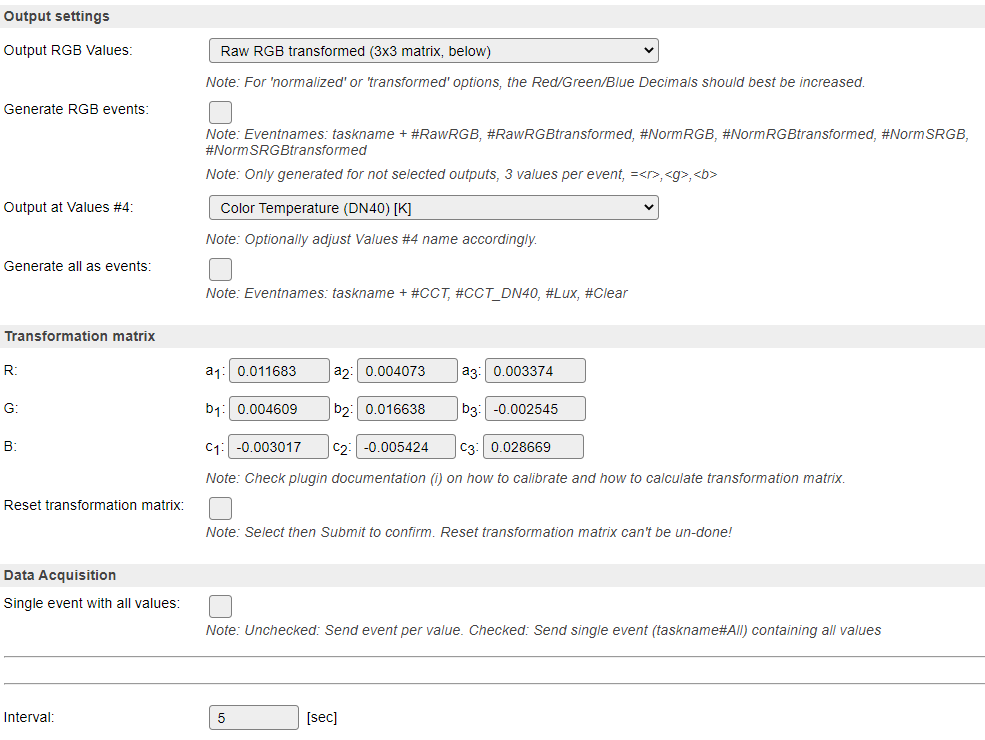

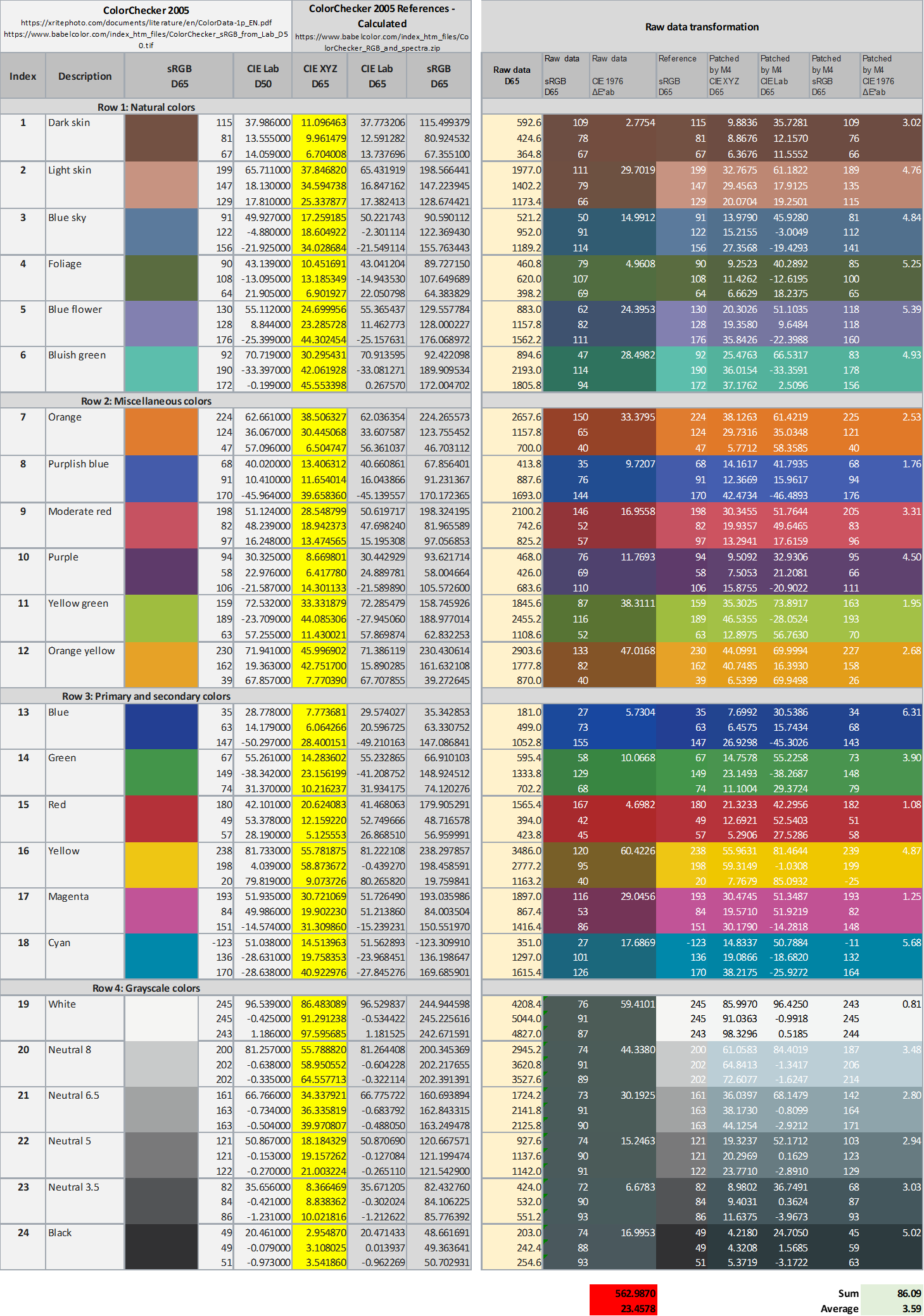

Transformation matrix¶

Example for a Transformation into the CIE-XYZ color space:

Most common and most accurate approach

| X* | | R‘ |

| Y* | = | M | * | G‘ |

| Z* | | B‘ |

- X*, Y* and Z* are the estimated CIE-XYZ values

- R', G' and B' are the responses from the sensor's Raw RGB output channels

- | M | is the transformation matrix based on your sensor calibration

Conversions from CIE-XYZ color space into RGB (e.g. sRGB, Adobe RGB (1998), …) or other color spaces are easyly to manage (see chapter “Conversions from CIE-XYZ color space into other color spaces”)

The sensor without any kind of calibration can only provide a raw color estimation (see chapter “Normalized RGB”)!

Please follow the chapter “Sensor calibration” to understand the procedure for setting up and to calculate a transformation matrix fitting to your specific need.

After applying transformation/calibration factors do NOT change your settings of Gain and Integration Time (see chapter “Conditions”)!

Rules examples¶

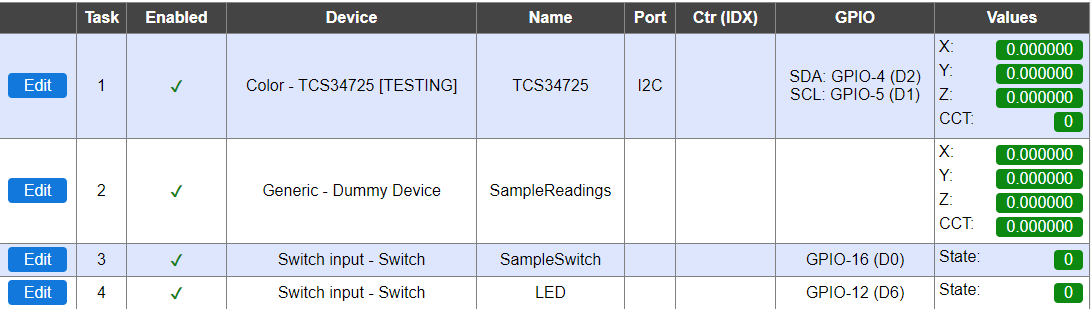

The following example is based on:

a Switch which will start a Sample and will indicate that the Sample is finished

an LED (onboard of your TCS34725 or placed somewhere else in your case) to illuminate what you’re trying to sense

a Dummy Device for the recording of your Sample Readings

a Rule Set for synchronization

On System#Boot do

Let,1,0 // LoopCounter

Let,3,0 // SampleMode off

Let,5,0 // Sample averages

Let,6,0

Let,7,0

Let,10,16 // SampleSwitch GPIO

Let,11,12 // LED GPIO

Pulse,[INT#11],1,1000

endon

on ResetSampleReadings do

TaskValueSet,%eventvalue1%,1,0 // SampleReadings

TaskValueSet,%eventvalue1%,2,0

TaskValueSet,%eventvalue1%,3,0

endon

on UpdateSampleReadings do

TaskValueSet,2,%eventvalue1%,%eventvalue2% // SampleReadings

if %eventvalue1%=3

GPIO,[INT#10],0 // SampleSwitch off

endif

endon

on Sample#State=1 do // SampleSwitch on

GPIO,[INT#11],1 // LED on

asyncevent,ResetSampleReadings=2 // SampleReadings reset

Let,3,1 // SampleMode on

TaskRun,1 // Sample start

endon

on TCS34725#X do

if [INT#3]>0 // SampleMode on

Let,1,[INT#1]+1 // LoopCounter

if [INT#1]>1 and [INT#1]<6 // Skip values for 1. Loop

Let,5,[VAR#5]+[TCS34725#X] // SampleAverages for Loop 2,3,4,5,6

Let,6,[VAR#6]+[TCS34725#Y]

Let,7,[VAR#7]+[TCS34725#Z]

elseif [INT#1]=6

Let,5,([VAR#5]+[TCS34725#X])/5

Let,6,([VAR#6]+[TCS34725#Y])/5

Let,7,([VAR#7]+[TCS34725#Z])/5

asyncevent,UpdateSampleReadings=1,[VAR#5] // SampleReadings update

asyncevent,UpdateSampleReadings=2,[VAR#6]

asyncevent,UpdateSampleReadings=3,[VAR#7]

GPIO,[INT#11],0 // LED off

Let,1,0 // LoopCounter reset

Let,5,0 // SampleAverage reset

Let,6,0

Let,7,0

Let,3,0 // SampleMode off

endif

TaskRun,1 // Loop

endif

endon

Indicators (recommended settings)¶

Indicator |

Value Name |

Range |

Interval |

Decimals |

Extra information |

|---|---|---|---|---|---|

Raw RGB |

|

|

0 |

|

|

Clear Channel |

|

|

0 |

|

|

CIE-XYZ |

|

|

6 |

|

|

Normalized RGB |

|

|

4 |

|

|

Correlated Color Temperature [K] |

|

|

0 |

|

|

Intensity of Ambient Light [Lux] |

|

|

0 |

|

Normalized RGB¶

Normalized RGB ≠ sRGB (not equal to sRGB)

Sum of Normalized RGB channels is 255

You’re losing information - Only a raw estimation (see: https://aishack.in/tutorials/normalized-rgb/)

Example for Yellow ColorChecker Patch [Index No 16, sRGB(238 198 20)]:

Raw RGB (Range: 0..65535) R : 3486.0

G : 2777.2

B : 1163.2

------------------------------------------------------------------

Sum : 7426.4

Normalized RGB (Range: 0..1) R : 3486.0 / 7426.4 = 0.469406

G : 2777.2 / 7426.4 = 0.373963

B : 1163.2 / 7426.4 = 0.156630

------------------------------------------------------------------

Sum : 1

Normalized RGB (Range: 0..255) R : 0.469406 * 255 = 120

G : 0.373963 * 255 = 95

B : 0.156630 * 255 = 40

------------------------------------------------------------------

Sum : 255

Compared to their corresponding sRGB values:

sRGB (Range: 0..255) R : 238

G : 198

B : 20

------------------------------------------------------------------

Sum : 456

Adjust sensor’s values (precision)¶

Use 6 digit precision for the 3 color channels if additional transformations into other CIE Color or RGB standards are required.

Where to buy¶

Store |

Link |

|---|---|

adafruit |

$ = affiliate links which will give us some money to keep this project running, thank you for using those.

More pictures¶

Sensor calibration¶

General information¶

Below calibration method is following “ams Color Classification with the TCS230” (https://ams.com/documents/20143/80162/ColorSensors_AN000518_1-00.pdf).

Reference Measurements¶

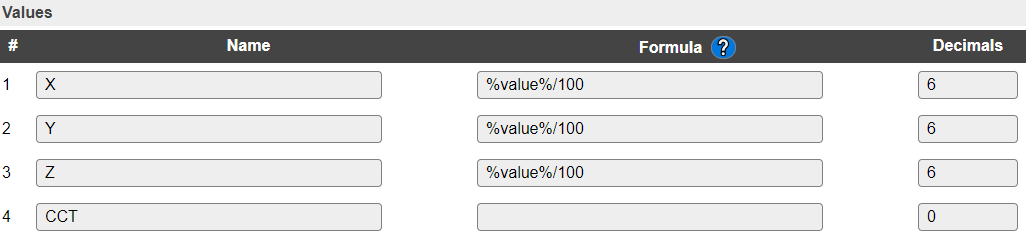

Color charts/references such as the ColorChecker can be perfectly used for reference measurements.

Because of its wide availability and use, its careful design, its consistency and because comprehensive spectrophotometric measurements are available, the ColorChecker has also been used in academic research into topics such as spectral imaging:

https://xritephoto.com/documents/literature/en/ColorData-1p_EN.pdf

https://www.babelcolor.com/index_htm_files/ColorChecker_RGB_and_spectra.zip

Above chart is converted from BabelColor: https://www.babelcolor.com/index_htm_files/ColorChecker_sRGB_from_Lab_D50.tif

Nominal chromaticities of ColorChecker patches in the CIE 1931 xy chromaticity diagram:

Conditions¶

Measurement under specific Light (Wavelength, Illuminance (lux), Color Temperature (CCT), Daylight, LED light, …)

Constant Distance between Light source <-> Object <-> Sensor

Constant Light Reflectance - Beam angel

Proper Gain and Integration Time settings

In case you illuminate via your LED monitor ensure proper monitor calibration first:

After applying transformation/calibration factors do NOT change your settings of Gain and Integration Time!

“White point” calibration - the most simple one¶

Good wikipedia article about color calibration (“Color balance”)

Illuminate a white paper with white/day light (please see above conditions) and measure sensor’s Normalized RGB values:

R'w = 77.4623

G'w = 90.4528

B'w = 87.0849

Calculate calibration factors for “White Point” [sRGB(255 255 255)]:

| R* | | 255 / R’w 0 0 | | R‘ |

| G* | = | 0 255 / G’w 0 | * | G‘ |

| B* | | 0 0 255 / B’w | | B‘ |

cR' = 255 / R'w = 3.291924

cG' = 255 / G'w = 2.81915

cB' = 255 / B'w = 2.928177

But these factors obviously are ONLY for raw color estimations (see chapter “Normalized RGB”) …

Mapping of sensor’s Raw RGB output channels to ColorChecker XYZ references¶

Most common and most accurate approach

Transformation matrix

| X"1 X"2 ... X"n | | R'1 R'2 ... R'n | -1

| M | = | Y"1 Y"2 ... Y"n | * | G'1 G'2 ... G'n |

| Z"1 Z"2 ... Z"n | | B'1 B'2 ... B'n |

- X"[1-n], Y"[1-n] and Z"[1-n] are the CIE-XYZ reference values for ColorChecker Patches

- R'[1-n], G'[1-n] and B'[1-n] are the responses from the sensor's Raw RGB output channels

- | M | is the transformation matrix

To find the inverse matrix: https://comnuan.com/cmnn0100f/cmnn0100f.php

Based on above calibration measurements the transformation matrix looks like

| 0.011683 0.004073 0.003374 |

| M | = | 0.004609 0.016638 -0.002545 |

| -0.003017 -0.005424 0.028669 |

But be careful: Above transformation matrix is ONLY working for specific conditions (see chapter “Conditions).

You have to setup and to calculate a transformation matrix fitting to your specific need.

Transformation into CIE-XYZ color space

| X* | | R‘ |

| Y* | = | M | * | G‘ |

| Z* | | B‘ |

- X*, Y* and Z* are the estimated CIE-XYZ values

- R', G' and B' are the responses from the sensor's Raw RGB output channels

- | M | is above transformation matrix

Conversions from CIE-XYZ color space into other color spaces¶

Conversions from CIE-XYZ color space into RGB (e.g. sRGB, Adobe RGB (1998), …) or other color spaces are easyly to manage:

Conclusion¶

A average of 3.59 ΔE*ab (Max ΔE*ab: 6.31) between ColorChecker XYZ references and their corresponding estimated XYZ values is not so bad for an 7.95$ cheap sensor ;-)

References¶

Adafruit product page: https://www.adafruit.com/product/1334

ams TCS34725 product page: https://ams.com/tcs34725

ams TCS34725 data sheet: https://ams.com/documents/20143/36005/TCS3472_DS000390_3-00.pdf

Lux and CCT Calculations using ams Color Sensors (DN40): https://ams.com/documents/20143/36005/ColorSensors_AN000166_1-00.pdf

Calculating Color Temperature and Illuminance using ams Color Sensors (DN25): https://ams.com/documents/20143/36005/TCS34xx_AN000517_1-00.pdf

Improving Color Sensor Lux Accuracy using ams Color Sensors: https://ams.com/documents/20143/36005/ColorSensors_AN000261_1-00.pdf

ams Color Classification with the TCS230: https://ams.com/documents/20143/80162/ColorSensors_AN000518_1-00.pdf

ams Colorimetry Tutorial (DN 20): https://ams.com/documents/20143/36005/LightSensors_AN000519_1-00.pdf

X-Rite ColorChecker reference data (2009): https://xritephoto.com/documents/literature/en/ColorData-1p_EN.pdf

Descriptions and pictures of the ColorChecker: https://www.babelcolor.com/colorchecker.htm

CIE Color Calculator: http://www.brucelindbloom.com/index.html?ColorCalculator.html

CIE Color Difference Calculator: http://www.brucelindbloom.com/ColorDifferenceCalc.html

Useful Color Equations: http://www.brucelindbloom.com/index.html?Math.html

Change log¶

Changed in version 2.0: …

added Major overhaul for 2.0 release.

Added in version 1.0: …

added Initial release version.